installation of vibration motor

ABB Low Voltage Motors Matrix

Low Voltage Motors Installation, ... dimensioned as to avoid the occurrence of vibration due ... ABB / Low Voltage Motors / Manual 122004 GB.

440 450 Electronic Vibration Switches Installation Manual

440 450 ELECTRONIC VIBRATION SWITCHES Installation Manual ... one on each end of the motor and ... 440 450 Electronic Vibration Switches Installation ...

Installation for vibration damping in drive .

Installation for vibration damping in drive connection of motor vehicles The Journal of the Acoustical Society of America 65, 1357 (1979 ...

An Analytical Approach to Solving Motor Vibration .

vibration the two levels will add when they are in phase and subtract when they are out of phase and then add again when they return to being in phase. This modulation will repeat at a frequency of 2 times the slip on 2 pole motors. Even at noload, twice rotation vibration on 2 pole motors will vary from 7200 cpm (120Hz) due to slip.

Mounting, Levelling and Vibration Control of: PUMPS ...

Sources of Pump Vibration If the pump and motor are well balanced and in good working order the only vibration ... types and installation scenarios because ...

Using vibration to install monopiles to reduce .

1year test to validate use of vibration to install large ... using vibration to install monopiles to reduce ... monopile installation in ...

MISTRAS NDT Services Installation of Vibration ...

Note that continuous monitoring of machine vibration is desirable for many reasons. First of all, it can provide protection from catastrophic failure by alarming a Control Room or even shutting down a machine if the vibration level is destructive.

Installation of vibration test systems .

Conditions for installation of IMV aircooled vibration test systems. Shaking tests require a 3axis vibration profile and 3 axial fixture. The lowest test ...

Vibration Problems With An Electric Motor For A ...

A case history is presented in which vibration related problems with two pole electric motors have delayed acceptance of the complete pump packages by the ...

Installation Operation Maintenance ROTARY SCREW ...

Installation Operation Maintenance ROTARY SCREW ... Compressor/Motor Coupling Installation ... customer must be prepared for package vibration and ...

Rubber Mounts Vibration Isolation and .

Antivibration rubber mounts are used mainly in vibration isolation of mechanical equipment and HVAC applications. Antivibration rubber mounts are ...

MachineCondition Monitoring Using Vibration

MachineCondition Monitoring using Vibration Analysis ... the condition of the motor plant maintenance costs. ... ately after installation in the shovel

Maintenance and Troubleshooting of Electric Motors

Maintenance and Troubleshooting of Electric Motors Reliance Electric Posted 11005 Motor Maintenance SCHEDULED ROUTINE CARE Introduction The key to minimizing motor problems is scheduled routine inspection and service. The frequency of routine service varies widely between applications.

Pump Vibration Goulds Pumps

pump installation. Excessive pump or motor vibrations ... coupling and misalignment between the motor and pump. pump vibration levels due to misalignment ...

Vibration Damping — Copter documentation .

Motor balancing can also reduce vibration and especially so for cheaper or larger motors. Balancing involves: Tightly fasten a small tie wrap around a motor (WITH NO PROP), trim off the extended tab and spin it up. Try multiple times, each time turning the tie wrap on the motor housing a bit until the vibration reduces or goes away.

The common malfunction of vibration motor .

The motor is a high precision equipment, which cannot be influenced by other materials. But because of the large applicability of vibration motor, it is hard to avoid the .

Balancing and Vibration Limits Peerless Pump

2. motor balance 3. hydraulic operation of pumpflow/tdh range 4. NPSHA cavitation 5. natural critical frequency VFD 6. nozzle loads/pipe strain 7. alignment/soft foot 8. .

Marley 5550 Vibration Switch SPX Cooling

/ Marley 5550 Vibration Switch / User Manual 071274. 2 Installation This bulletin should be used by experienced personnel as a guide to the

Vibration Isolators and Shock Mounts

Tech Products is a leading supplier of vibration control products to the power generation industry. Applications range from small 2KW portable generators to larger 500KW systems. Isolators are used to eliminate the transmission of engine vibration to the supporting structure (frame, ground etc.).

Bibliography of Technical Papers Vibration

Wireless Vibration Monitoring for Condition Based Maintenance Cooling Towers: Gerry Nadley, MachineTalker, Inc: 2008: Abstract: An overview of peer to peer wireless ad hoc networks explaining basic characteristics, and modes of operating. This will include reliability and ease of operating and installation.

VIBRATION ISOLATION SECTION 15242 .

Vibration isolation. Seismic control for equipment. Piping Seismic Separation Joints. RELATED WORK. Section 03300 Cast in Place Concrete: Section 15016 Equipment Installation. Section 15220 Seismic Bracing. PERFORMANCE REQUIREMENTS. Provide vibration isolation on motor driven equipment over HP, plus connected .

Condition Monitoring of Electrical Machines ABB .

(identifying mechanical condition like bearing, installation quality etc) ... Overall vibration readings in Motor BFP 3C, serial number:

Installation Maintenance Manual Nuway

Installation Maintenance Manual ... using antivibration ... Electrical Installation Always ensure that the motor data plate details coincide with ...

Installation of Wireless Remote Control .

· Wireless Remote Control Vibration Alarm Antitheft Lock Price: ৳550 Call us + + or, SHOP NOW from http ...

Significance of vibration diagnosis of rotating machines ...

for example Ð Electric Motors, Centrifugal pumps, Electric Generators, Turbines, etc. are ... installation vis vis the vibration parameters

Latest Posts

- مطحنة الأسطوانة jurnal pdf

- مصانع تكسير خام الذهب في مصر

- كسارة مخروطية متنقلة للبيع في المملكة العربية السعودية

- دراسة جدوى لمصنع السكر الأردن

- مطحنة عمودية لرمل السيليكا

- رمل السيليكا الكوارتز للمسبك

- مطحنة عمودية طحن الأسمنت

- تكلفة مصنع معالجة المسحوق في مصر

- مصنع تجهيز روك جولد

- كسارات الصخور للبيع في جنوب ليبيا فقط

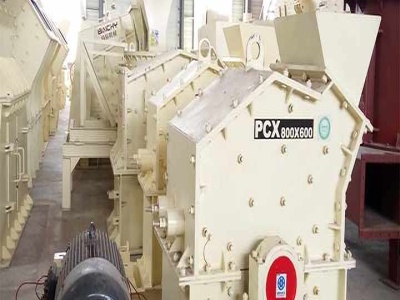

- معمل كسارة صيني في العراق

- عملية إنتاج الورق الحجري

- الفحم كسارة المحمول

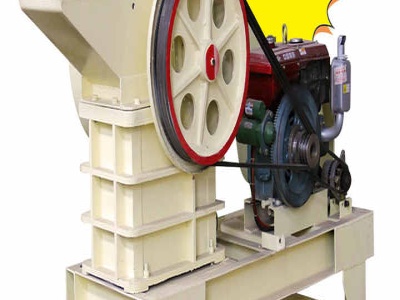

- آخر التطورات كسارة الفك

- مصنع البنتونيت في الجزائر

- rise crushing machine powder machine

- moisture content equipment

- carbon steel castings crusher components

- greasemonkey scripts mafia wars facebook

- quartz decorative stone for sale

- how much does grinding fuel machine cost in nigeria

- cold rolling mills wezel

- cement plant grinding plant s machine details

- used gold ore crusher exporter in malaysia

- const crushing eg and supplies

- pile head crushing machine

- small scale rock mill

- pot grinders for sale

- project report of metal crusher unit

- iron ore pulverizer equipment